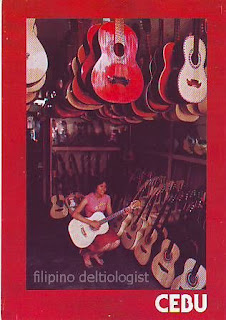

Postcard Type: View card with red border

Printed by: JMC Press, Inc., Quezon City

Purchased at Goodwill Bookstore

The postcard shows Cebu's handcrafted guitars, one of the popular products of the province, aside from lechon (suckling pig), and dried mangoes and fish.

The seat of the guitar making industry in Cebu is in Mactan Island, particularly Maribago in Lapu-Lapu City. One can also visit the guitar stores at the Quezon National Highway in Lapu-Lapu City, and in Lincoln Street near the Carbon Market district. Famous guitar makers are the families of the Alegre, Lumanog, Malingin, and the three sisters Lilang, Susing, Celia.

Guitars are made of various kinds of soft and hard woods, from nangka (jackfruit) to the more prized naga (narra) and kamagong (ebony). These may come attractively decorated or inlaid with shell.

The back of the postcard reads:

Cebu is noted for excellent craftsmen especially in the making of inexpensive native and Spanish guitars.

Cebu is noted for excellent craftsmen especially in the making of inexpensive native and Spanish guitars.

HISTORY

Gitara or kitara (from the Spanish guitarra) is actually a Spanish introduction. The guitar industry began in Cebu when the Spanish friars needed to repair the guitars they were using. At that time, guitars usually came from Mexico. Instead of waiting, the friars hired people from Opon village in Mactan Island to make new guitars and repair the ones they had.

Making a guitar involves seven steps:

(1) The craftsmen selects the wood which may be of two kinds: hard (almasiga, narra, agot-agot) or soft (palo china, nangka).

(2) One of the seven are chosen: ukulele boy 22.5 in; SPanish guitar 39 in; or any of the types with stylizes shoulder-twist 36 in; cut-away 39 in; striated 38 inches; classic 37 in.

(3) Craftsman cuts the wood and fashions the frame, mostly with a chisel.(4) Next comes the parts, nine in all: arched top (pala, machine heads (liso), nut (sihas), fingerboard (apurro or brazo), frets (tratse), strings (koldas), shoulder (abaga), sound hole (baba), and bridge (puente or bangil).

(5) The front and back parts are joined together and tied with rope.

(6) The handle is attached and dried in the sun for two or three days, before the (7) final varnishing.

SOURCES:

World's finest guitars- Cebu guitars

The Land of Guitars

Cebu’s Famous Guitars

Guitar Making, pp. 94-95, Cebu: A Places For All Seasons by Joyce Garcia Dizon; Bookmark, Inc.

No comments:

Post a Comment